DTMF is a method of representing digits with tone frequencies, in order to transmit then over an analog communications network. Here DTMF can be used to control electronics appliances remotely using our mobile handset or fixed landline .In this circuit main components are dtmf decoder, demultiplexer and relay driver circuit. Its typical applications are security system and control almost every electronics devices from anywhere in the world by using mobile communication network. This Mobile Switching Device Using DTMF Project was done in Electronics and Communication Engineering.

IR-2110 based squarewave inverter by using 555 Timer

Description of IR-2110 based squarewave inverter by using 555 Timer: An inverter is a device which converts dc voltage to output ac voltage at required voltage and frequency.The output ac voltage frequency can be fixed or varied .The variable frequency output voltage have several applications in conveyor,machine tool testing.This convertion can be done by controlled power on and power off devices like MOSFET and IGBTs.

IR-2110 is a high speed,high voltage power MOSFET and IGBT driver. This inverter converts the dc voltage into ac output voltage of squarewave pulses by using two jk flif flofs.

Dc signal is given to the 555 Timer,it produces squarewave pulses.these squarewave pulses are given to the two JK flif flofs,the two pulses are converted into four signals and are given to the IR-2110.From the inverter the signals are given to the four IGBTs,then the signal is converted to ac signal of required voltage and frequency.

PLC Controlled In D1 Charging Conveyor For Blast Furnace In Vizag Steel Plant

Project Title: PLC Controlled In D1 Charging Conveyor For Blast Furnace In Vizag Steel Plant

Language of Implementation: A programmable logic controller (PLC)

Project Description:

The main aim of the PLC Controlled In D1 Charging Conveyor For Blast Furnace In Vizag Steel Plant is to the braking flaps are located in cooling bed of 120 meters length is divided into two parts 60 meters each. One part covers the first half of the cooling bed and other part covers the remaining half. Each part has an number of individual flaps of about one meter length , and 200mm width, connected to the lengthy shaft covering one half of the cooling bed area. Each shaft is driven by a 52KW separately excited DC motor. These motors are in turn controlled by the drive control system (Drive 1 & Drive 2).

Industrial Robot Using Micro Controller

Objective:Industrial Robot projects objective is to develop a robotic application for industries which can move in circular, rectangular, angular straight line path and which can work on hard and plane surfaces.

Robot is integrated with different sensors which can sense parameters like temperature and detect fire and obstacles in its path.

Functioning:DC servomotor is used for controlling two pairs of wheels set to the robot. DC servomotor consists of wound armature and permanent magnet rotor. In order to control the speed of the DC motor pulse width modulation technique is used by providing dc supply to armature.

Micro controller is used to generate DC supply to robot in the form of pulse width modulated signal. This robot is useful for industries for sorting assembling and surveillance.

The following features can be provided in this project

Fire detection:

In order to detect fire accidents Robot is assembled with photo sensor like LDR. When sensor senses fire it will send information to micro controller and then it will set on the buzzer.

Obstacle detection:

For detecting obstacles in the path IR sensors are fixed with robots which will detect obstacles and set on the buzzer when the obstacle is cleared buzzer will off.

Wireless remote control:

This robot runs using RF wireless technology, we can operate using a remote.

download Industrial Robot Using Micro Controller Project.

Industrial Power Management System

Design Objective of the Project:Industrial Power Management System project is a integration of different components like protective relays, remote I/O modules, Communications, monitoring, and engineering tool sets.

Industrial Power Management System project will provide you to develop and specify the most efficent, cost saving, and full-automated power management system useful for today. In order to develop this application we will specify major hardware required to develop a full featured power management system. Then under second stage we will explain on factors like economic benefits and reliability.

This project completely involves in the monitoring of various parameters of powersystem and provides indication and control for the same.This project uses the powerful micro controller and the information gathered by the microcontroller is sent to the PC for processing.

Hardware requirements:

- RS232

- Micro Controller

- Signal Conditioning Circuits

- Analog Inputs

Solar Electric Charge Controller and Portable Power Supply

Solar Electric Charge Controller and Portable Power Supply projects main aim is to develop a micro controller based device which will use solar energy to recharge a DC battery. In order to setup this system solar panel should work at an optimal power. In order to generate maximum and consistent power from solar panels controllers will vary voltage across the solar panel. Here we use pulse width modulation techniques to charge the DC battery by maintaining voltage level.

The main electronic components of our product are the solar panel which provides power, generated power is supplied to rechargeable batteries, Circuit is used for improving power sharing between two,and a LCD and two LEDs as outputs to the user.microprocessor For loading program on to PIC18F452 chip we use serial port and receive data output on a terminal program (such as HyperTerminal).

Hardware used in this project:

- DC DC converter

- PIC Micro controller

- Micro chip for current sensing.

- LCD Display.

- Serial port for communication.

Single Dc Motor Speed Control By Tv Remote

Abstract:– Here is a very simple example of DC motor speed control by changing firing angle of TRIAC with the help of micro controller AT89c52.In order to mange speed variations for the motor we use firing angle by using thyristor. This method is widely used method for speed variations in DC motor systems. In this project we use AT89C52 controller in the place of DIAC for firing TRIAC.A zero crossing detector circuit is used here to interrupt AT89C52 after every 10 ms. After getting an interrupt AT89C52 will fire TRIAC after some delay from 1 to 9 ms. This will reduce the current input to motor and so the motor speed will reduce.By changing the delay time with the TRIAC speed variation can be managed.

Software logic: –The complete operation is based on the software embedded in micro controller P89C51ED2.C is the programming language used in this application. Each function written has different functionality like ext1,ext2 and delay in speed. Programmed code is written on to micro controller.

download Single Dc Motor Speed Control By Tv Remote Project.

Energy Saving Systems For Railway Platforms

Energy Saving System For Railway Platforms Projects main idea is to develop a micro controller based project for saving energy for railway platforms.

NEED FOR THE PROJECT: Normally in railway platforms Whether the Train is there or not, Unnecessarily all Lights in the platforms are Glowing. In present system there is lot of usefulness wastage of energy. Maximum energy is wasted at the time of no train on the platform. All the lights televisions etc are not stopped when there is no use.

AIM OF OUR PROJECT

Our project is a computer controlled system Wherein all the train arrival and departure timings are entered in it.

So we can able to switch on all the lights When the train is about to come or to leave. During the other times we can glow Some important lights so that the platform will not be left completely dark.

In this project micro controller application setup is installed at each platform. Using a remote PC we will command micro controller unit for controlling lighting system for each platform.

download Energy Saving Systems For Railway Platforms Project.

Scada Based Intelligent Multi Parameter Monitoring System With Lcd Display

SCADA BASED INTELLIGENT MULTI PARAMETER MONITORING SYSTEM is implemented using micro controller and sensors. Sensors will send information continuously to micro controller through which controller will analyze the result and take required action. Micro controller used in SCADA system works at a 9600 Band Rate.

SCADA means Supervisory control and Data Acquisition System. Which is used in industries for monitoring and controlling different processes from a control room using a SCADA system?

At this brand rate we can monitor different changes that occur in particular parameter and take required action.

For easy view and monitoring this application information about all the parameters are displayed on LCD screen.

Graphical display is used for variations of each parameter on time factor scale. This procedure will provide user accurate analysis on different processes.

In this paper we will explain in detail using block diagram and performance on DC Voltage measurement, DC current Measurement, AC Voltage Measurement and Frequency measurement.

download Scada Based Intelligent Multi Parameter Monitoring System With Lcd Display Project.

Ac Induction Motor Speed Control Using Constant V/F Method.

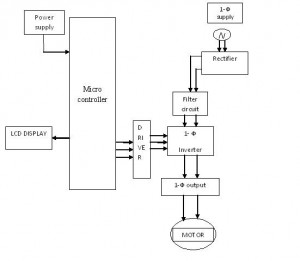

AIM: AC Induction Motor Speed Control Using Constant V/F Method projects main aim is to develop a micro controller based speed control application using variable frequency control method. This project is a simple application which can be done with a low cost.

With a cost effective process it is easy to control AC induction motor using one of the most popular voltage frequency ratio technique.

Description: In present scenario each and every industries are using DC motors, reason behind this is it is easy to control the speed of DC motor compare to AC motors. But there are few drawbacks in DC motors compare to AC motors.

Maintenance for DC motors are more compare to AC motors. By introduction of power electronic devices DC motors are replaced with AC motors because speed control problem had solved with power electronics devices.

In this paper we will cover how power electronic devices works with induction motors and we explain in detail about supply frequency and many other factors.