In Laser Torch Based Communication System project we implemented a new generation “laser torch-based voice Transmitter and receiver” which is a good replacement for the present day communication systems.

Starting from the optical fiber communication wireless communication had taken several modifications recently laser based communication is gaining much attention in the field of space research and satellite communications.

Laser based voice transmitter and receiver:

Key points:

- Laser torch acts as a carrier for the voice signal to be transmitted.

- It is a wireless open channel system

- Ability to transmit voice signals up to 500 meters.

Figure: block diagram representation of Laser Torch Based Communication System.

Condenser MIC:

Capacitor based electrostatic microphone, is a most sensitive for the low amplitude signals also. Its main function is to convert the audio signal into electrical signal. These are ideal for high volume work.

Youtube video link to view circuit diagram, block diagram.

http://www.youtube.com/watch?v=PFE7Yz_sAp8&feature=youtu.be

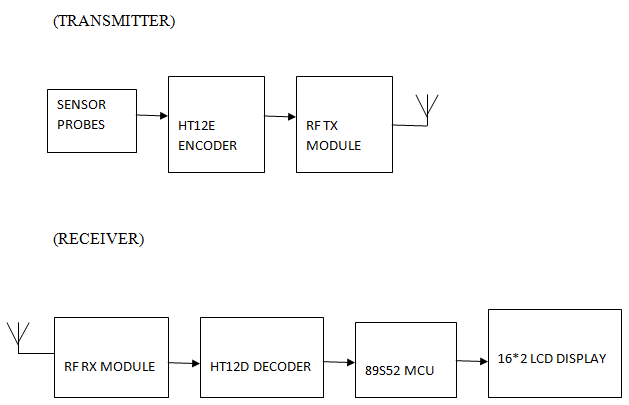

Transmitter section:

The transmitter section is comprised of pre amplifier, operational amplifier, and heat sink for absorption of noise in the signal, VR, and laser diode.

Laser torch:

The laser torch acts as a medium for the laser. And it can transmit wavelength of range 780nm – 920nm.

Download Laser Torch Based Communication System Project Report

Receiving section:

The receiver section of the laser communication system has photo detector for sensing the laser light, Audio amplifier for better audibility, common emitter amplifier and a loud speaker i.e. transducer.