BTech – MTech Mechanical final year Projects for 2013-2014, 2014-2015 Academic Students.

(Fabrication, Production, Robotics, Thermal, Mechanical, Automobile, Aero, Tool & Die)

1 – 90 Degree Turning Steering Mechanism – Four Wheeler

2 – Abrasive Belt Grinde

3 – Abrasive Jet Machining

4 – Accident Avoiding System for Cutting Machine

5 – Accident Avoiding System for Punching Machine

6 – Accident Preventing System for Automatic Pneumatic Printing Press

7 – Activated Carbon Manufacturing Plant

8 – Aero Plain Controlling System

9 – Agricultural Motor Pump Running Using Solar Power

10 – Ai Based Path Finding Cum Video Analysing Robot

11 – Air for Four Wheelar

12 – Air for Two Wheelar

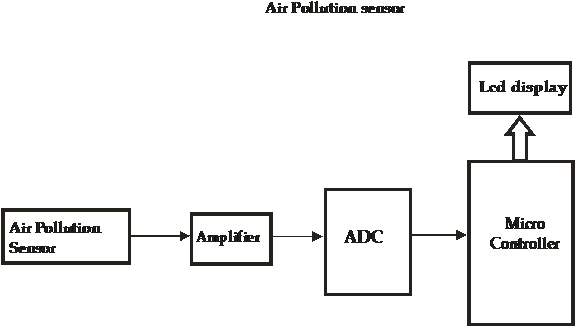

13 – Air Pollution Monitor

14 – Anti Hijack System for Aero Plane

15 – Anti – Lock Braking System – Frame – Hydraulic

16 – Anti – Lock Braking System – Hydraulic

17 – Antilock Braking System – Frame – Pneumatic

18 – Auto Braking System

19 – Auto Clutch for Automobile

20 – Auto Indexing Gear Cutting Attachment for Pneumatic Shaping Machine

21 – Automated Track Guided Vehicle (Atgv)

22 – Automatic Train Station Announcement System with Bomb Detection

23 – Automatic Ac Control System For Cars

24 – Automatic Acceleration Controlling System In Traffic Signal

25 – Automatic Accident Avoiding System In Machine

26 – Automatic Accident Avoiding System In Pneumatic Bend And Bend Removing Machine

27 – Automatic Bar Feeding Mechanism For Cutting Machine

28 – Automatic Board Cleaner

29 – Automatic Bottle Filling System

30 – Automatic Bouring Mechnaism For Boundry

31 – Automatic Break Failure Indicator

32 – Automatic Car Parking System

33 – Automatic Clutch and Braking System for Four Wheeler

34 – Automatic Coil Winding Machine

35 – Automatic Dam Shutter Controlling System

36 – Automatic Dam Shutter Open – Close System

37 – Automatic Differential Unit Locking System

38 – Automatic Dim – Bright Head Light Controller

39 – Automatic Dish Washing Machine

40 – Automatic Distance Mesurement and Braking System Using Ultrasonic

41 – Automatic Door Open – Close System

42 – Automatic Double Axis Welding Machine

43 – Automatic Double Axis Welding Robot

44 – Automatic Drilling and Tapping Machine

45 – Automatic Electro Magnetic Clutch

46 – Automatic Electro Platting Coating System

47 – Automatic Electro – Hydraulic Brake

48 – Automatic Electro – Hydraulic Jack – Fully

49 – Automatic Electro – Hydraulic Jack – Semi

50 – Automatic Embossing Drilling Machine

51 – Automatic Foot Dust Vacuum Cleaning Machine

52 – Automatic Gear Changer In Two Wheelers – Pneumatic Modelx

53 – Automatic Gear Tramission Fro Two Wheeler

54 – Automatic Hand Break Release

55 – Automatic Head Light Alignement System

56 – Automatic Head Light Dim – Bright & Engine Over Heat & Break Failure Controller

57 – Automatic Head Light Dim – Bright Controller And Engine Over Heating Alarm

58 – Automatic Head Light Dim – Bright Controller

59 – Automatic High Speed Bottle Washing Machine

60 – Automatic Hydro Pneumatic Lubricating System

61 – Automatic Industrial Fire Fighter (Semi)

62 – Automatic Laminating System

63 – Automatic Lamination Machine

64 – Automatic Laser Guided Punching Machine

65 – Automatic Lubrication System

66 – Automatic Lubrication Unit

67 – Automatic Magnetic Accident Preventing System For Train

68 – Automatic Musical Water Foundation

69 – Automatic Packing Control Machine for Industrial Applications – Fully – Pneumatic

70 – Automatic Paint Spraying Equipment

71 – Automatic Paint Spraying Pick and Place Equipment

72 – Automatic Paint Spraying Pick and Place Robot

73 – Automatic Paper Counting Machin

74 – Automatic Parking Braking System

75 – Automatic Petrol Bunk

76 – Automatic Pneumatic Bumper for Four Wheeler – Without Wheel Sensor

77 – Automatic Pneumatic Cutting and Grinding Machine

78 – Automatic Pneumatic Grinding Machine (Semi – Auto Feed Mechanism)

79 – Automatic Pneumatic Hammer

80 – Automatic Pneumatic High Speed Hack Saw Machine

81 – Automatic Pneumatic High Speed Sheet Cutting Machine

82 – Automatic Pneumatic Paper Cutting Machine

83 – Automatic Pneumatic Printing Press

84 – Automatic Pneumatic Punching and Riveting Machine

85 – Automatic Pneumatic Punching Machine

86 – Automatic Pneumatic Ramming Machine

87 – Automatic Pneumatic Reciprocating Grinding Machine

88 – Automatic Pneumatic Riveting Machine

89 – Automatic Pneumatic Shaping Machine

90 – Automatic Pneumatic Stand for Two Wheeler

91 – Automatic Pneumatic Tapping Machine (Semi)

92 – Automatic Pneumatic Valcanizing Machine

93 – Automatic Pneumatic Vice and Jack

94 – Automatic Pneumatic Water Pumping System

95 – Automatic Potato Chips Making Machine

96 – Automatic Power Saving Punching Conveyor

97 – Automatic Pressure Control Volve Open Close System

98 – Automatic Punching Conveyor

99 – Automatic Punching Machine

100 – Automatic Railway Gate Controller – Pneumatic Gate – Plc

101 – Automatic Railway Gate Controller

102 – Automatic Railway Track Crack Detecting Robot – Obstacle

103 – Automatic Rain Operated Wiper

104 – Automatic Reverse Braking And Distance Mesurement System Using Ultrasonic

105 – Automatic Side Stand with Breaking Locking System

106 – Automatic Spiral Punching Machine

107 – Automatic Steering Mechanism

108 – Automatic Vegetable Cutting Machine – Semi

109 – Automatic Vehicle Locking System By Withouthelmets

110 – Automatic Vehicle over Speed Indication And Controlling System

111 – Automatic Wheel Air Filling System

112 – Automatic Wiper

113 – Barrel Lifting

114 – Battery Car – Engine

115 – Battery Cycle

116 – Busbar Feeder Controller Using Plc

117 – Button Operated Electr – Magnetic Gear Shifting System

118 – Cam Vice

119 – Car And Bus Reverse Operating Navigation System Using Ir Rays

120 – Cell Phone Controlled Material Handling Vehicle

121 – Cell Phone Controlled Solar Vehicle

122 – Coffee Maker

123 – Coil Winding Machine

124 – Coin Box Based Automatic Wheel Air Filling System

125 – Compreseed Air Engine

126 – Compressed Air Production Using Speed Breaker

127 – Compressed Air Production Using Vehicle Suspensor

128 – Concave Attachment for Lathe

129 – Concave Attachment for Shaper

130 – Conveyor Automation – Fully

131 – Conveyor Automation

132 – Conveyor Operated Robot

133 – Cooling Tower with Power Generation System

134 – Cooling Tower

135 – Curcullar Cutting Machine

136 – Cylindrical Grinding Machine

137 – Cylindrical Tapping Machine

138 – Degree Turning Steering Mechanism – Four Wheeler

139 – Design and Fabrication of Vertical Axis Windmill

140 – Digital Hydraulic Jack – 1

141 – Dosai Maker

142 – Drips Rate Monitor & Alarm

143 – Driverless Car

144 – Dsp Based Path Finding Vehicle

145 – Effieciency Increasing System by Using Preheatng Method

146 – Electric Car

147 – Electric Two Wheeler with Rechargable Battery

148 – Electrical Power Generation Using Foot Step

149 – Electrical Power Generation Using Railway Track

150 – Electrical Power Generation Using Shock Absorber

151 – Electrical Power Generation Using Speed Brake

152 – Electricity and Water Pumping System Using Wind Mill

153 – Electro Magnetic Shock Absorber

154 – Electromagnetic Scrap Removing Machinex

155 – Elimination of Carbon Particles from Exhaust Gas

156 – Emergency Braking System

157 – Energy Conservation in Steam Power Plant

158 – Engine Overheat Alarm

159 – Enhancing User Experience At Museums (Treasury) Using Smart Phones

160 – Fabrication of Electrical Energy from Speed Breakerx

161 – Fabrication of Homemade Air Conditionerx

162 – Fabrication of Hydraulic Power Plant

163 – Fabrication of Industrial Trolley

164 – Fabrication of Magnetic Levitation Trainx

165 – Fabrication of Multi Spindle Drill Head

166 – Fabrication of Pneumatic Vice

167 – Fabrication of Safety Elevator Give the Miner A Brakex

168 – Fabrication of Solar and Wind Train

169 – Fabrication of Solar Water Coolerx

170 – Fabrication of Wind Mill

171 – Fabrication of Windmill and Controlling The Direction

172 – Fabrications of Pedal Power 4 Wheel Steering Mechanismsx

173 – Fiber Extracting Machine

174 – Film Roll Cutter

175 – Floor Cleaning Machine

176 – Four – Axis Material Handling Robot

177 – Friction Welding Machine

178 – Fuel Injection

179 – Fuel Processing Technology

180 – Gasifier

181 – Gear Cutting Attachment For Lathe

182 – Gear Type Injection Moulding Machine

183 – Gps Based Automatic Vehicle Accident Information System – Two Wheeler

184 – Grass Cutter

185 – Grinding Attachment For Lathe

186 – Gringing Machine

187 – Hand Propulsion and Steering Dampening For Three – Wheel Vehiclex

188 – High Speed Portable Pipe Cutting Machinex

189 – Home Appliance Turbine

190 – Home Flour Mill

191 – Horizontal Axis Wind Mill

192 – Horizontal Turbine Type Domestic Wind Mill

193 – Hot and Cold Water Despensor

194 – Hybrid System for Home

195 – Hybrid Vehicle Two Wheeaear

196 – Hybrid Vehicle

197 – Hydraulic Cylinder Liner Puller

198 – Hydraulic Fork Lifter

199 – Hydraulic Lift with Power Pack

200 – Hydraulic Lift with Pressure Booster

201 – Hydraulic Lift

202 – Hydraulic Mobile Crane

203 – Hydraulic Pipe Bending Machine

204 – Hydraulic Press with Power Pack

205 – Hydraulic Puller for Automobile

206 – Hydro Power Plant

207 – Hydro – Pneumatic Clamping System

208 – Hydro – Pneumatic Vice with Pressure Booster

209 – Hydrogen Engine cum Lpg

210 – Hydrulic Screw Jack

211 – Industrial Boiler Flame Remote Adjustment System

212 – Injection Moulding Machine

213 – Installation of Diesal To Lpg

214 – Installation Of Lpg To Two Stroke Gasoline Engine

215 – Intelligent Motorized Hydraulic Jack

216 – Intelligent Motorized Wall Painting Crane

217 – Involute Gear Profile Error Detector

218 – Lathe Coolant Pump

219 – Lathe With Milling Attachment

220 – Machanical Mini Plastic Crusher Machine

221 – Magnetic Shock Absorber

222 – Magnetic Suspension System

223 – Manual Sheet Rolling Machine

224 – Material Dimension Analysing Robot

225 – Mechanical Grass Cutter

226 – Mini Jet Engine

227 – Mini Robot Car

228 – Mirror Cutting Machine By Using Compressed Air

229 – Modern Pneumatic Mirror Cuttingx

230 – Mosaic Polishing Machine

231 – Motorized Jib Crane

232 – Motorized Screw Jack

233 – Motorized Sheet Metal Rolling Machine

234 – Motorized Trolley

235 – Motorized Wheel Chair

236 – Multi Fuel Engine

237 – Multi Point Grease Gun

238 – Multi Process Cutter

239 – Multi – Functional Wind Mill

240 – Multi – Purpose Dryer And Heater

241 – Multi – Purpose Machine

242 – Multi – Speed Gear Box

243 – Multi – Spindle Drill Holder

244 – Noise Control of Two Stroke Petrol Engine Using Aqua Silencer

245 – Oil Pump Testing Equipment

246 – Paint Mixing Machine

247 – Pantograph Universal Gas Cutting Machine

248 – Pedal Operated Wash Basinx

249 – Pedal Opertaed Water Pumping System

250 – Pedal Washing Machine

251 – Pedestal Spot Welding Machine

252 – Pelton Wheel Turbine

253 – Phenumatic Jcb Machine

254 – Pick and Place Jumping Robot With Remote Control

255 – Pipe Thread Cutiing Machine

256 – Plant Cutter

257 – Pneumafil Controller

258 – Pneumatic Acralic Sheet Bending Machine – Frame

259 – Pneumatic Arc Welding Machine

260 – Pneumatic Auto Feed Sheet Cutting Machine

261 – Pneumatic Bearing Press

262 – Pneumatic Door Open – Close System

263 – Pneumatic Double Axis Welding Machine

264 – Pneumatic Drill Jig

265 – Pneumatic Drilling And Tapping Machine

266 – Pneumatic Drilling Machine

267 – Pneumatic Drilling

268 – Pneumatic Four – Axis Material Handling Equipment

269 – Pneumatic Injection Moulding Machine

270 – Pneumatic Jack

271 – Pneumatic Jack

272 – Pneumatic Pick and Place Robot with Remote Control

273 – Pneumatic Pick and Place Robot with Video Camera

274 – Pneumatic Quick Return Mechanism

275 – Pneumatic Rotary Grinding Machine

276 – Pneumatic Sheet Bend Removing Machine

277 – Pneumatic Vice

278 – Quick Jackx

279 – Radial Plunger Pump

280 – Railway Track Disconnect Detection System

281 – Reaction Turbine

282 – Regenerative Braking Systemx

283 – Remote Controlled Sofa Comfort

284 – Remote Controlled Solar Vehicle

285 – Remote Controlled Weapon System

286 – Remote Operated Pnematic Material Handling Robot

287 – Robot with Crane System (1)

288 – Robot with Crane System

289 – Seed Dryer

290 – Sensor Operated Autofeed Punching Machine

291 – Sensor Operated Automated Track Guided Vehicle (Atgv)

292 – Sensor Operated Automatic Ramming Machine

293 – Sensor Operated Automatic Water Level Indicator and Controlling System

294 – Sensor Operated Intelligent Braking

295 – Six – Axis Material Handling Robot

296 – Solar Based Electromagnetic Breaking System

297 – Solar Cycle

298 – Solar Operated Robot

299 – Solar Tracking Vehicle

300 – Steam Power Plant

301 – Thermo Electric Refrigerator

These are the latest Mechanical Projects for all BTech, MTech Students. Contact us for more details.