Bag Security is a device developed in partial fulfillment of the course of Microcontroller and its applications that gives an indication to the owner whenever the Bag zip is opened when it is carrying. This School Bag Security project also displays the number of books in the bag which is useful for children below 10 years to verify whether they are carrying the same number of books they bought from home or not.

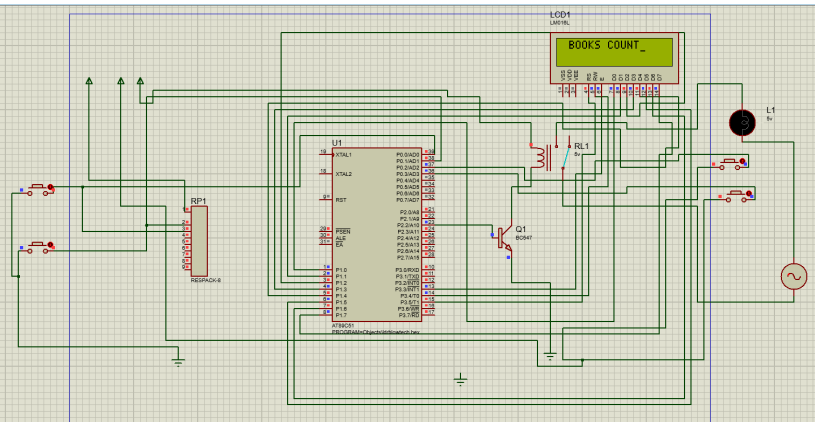

CIRCUIT DIAGRAM:

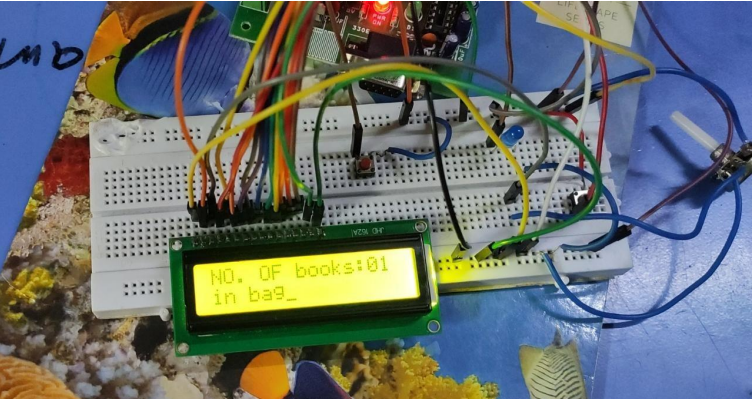

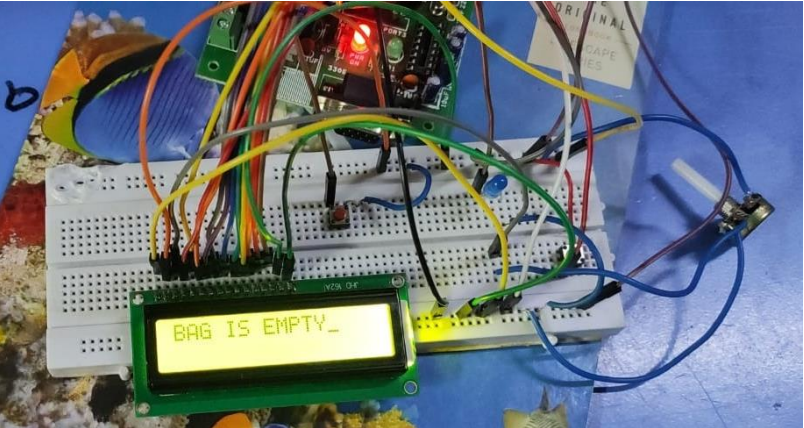

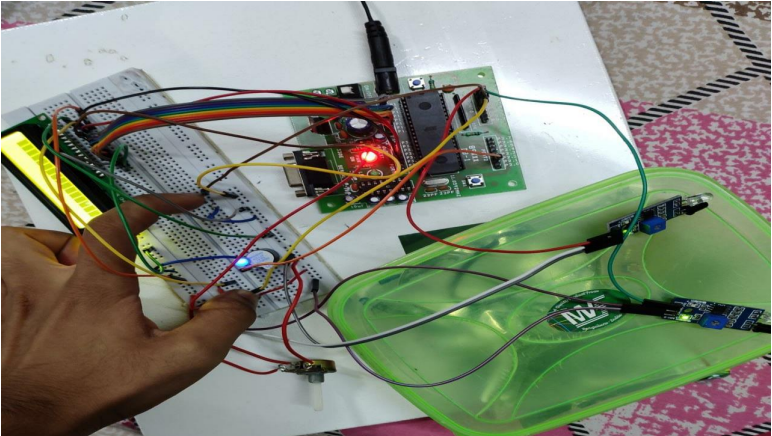

OUTPUTS IN BOTH PROTEUS AND HARDWARE:

CASE 1: INCREMENT OF BOOKS:

EXPLANATION:

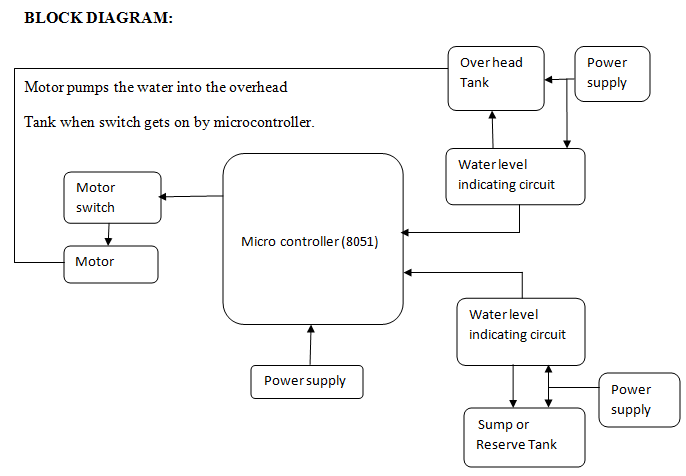

For increment first, the IR sensor1 will be detected and then IR sensor2 will be detected then only the book will be increment. IR sensor1 should be placed near the bag zip and IR sensor2 should be placed below the IR sensor1.

This shows the connections for our project left side two switches are IR sensors and the left side two switches are one switch and another IR sensor

CASE 2: DECREMENT OF BOOKS:

EXPLANATION:

For Decrement first, the IR sensor2 will be detected and then IR sensor1 will be detected then only the book will be decrement. IR sensor1 should be placed near the bag zip and IR sensor2 should be placed below the IR sensor1.

CASE3: WHEN ZIP IS OPEN:

EXPLANATION for case3:

The buzzer should ring only when we are carrying the bag and also when the zip is opened the truth table explains that. So, we kept the switch on the bag Zip and the Ir sensor below the zip inside the bag. When the switch is on and also the Ir sensor detects the light then the buzzer or LED will be ON.

CONCLUSION:

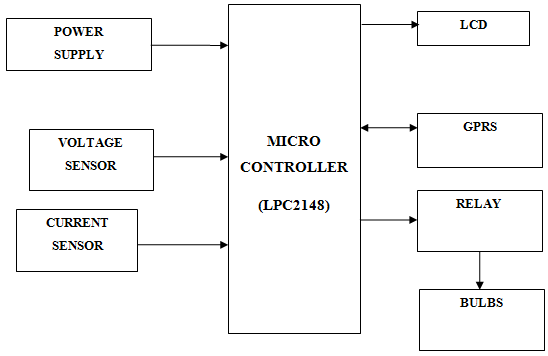

We have designed a device that will ring the buzzer only when we are carrying the bag and also when the zip is opened. And also, we have included an LCD which displays the number of books in the Bag.

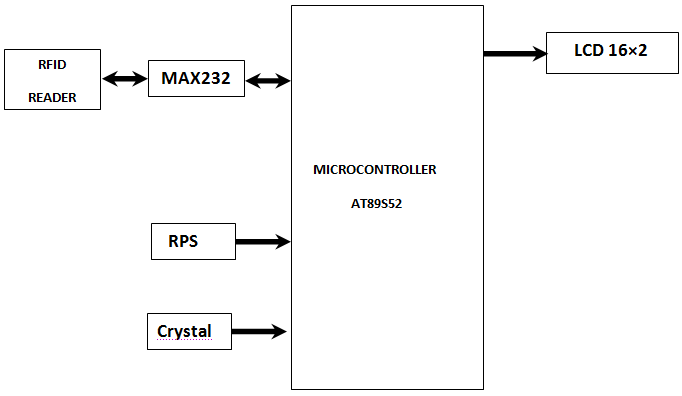

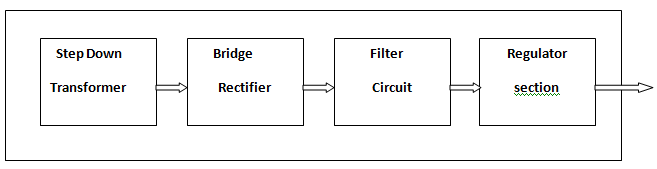

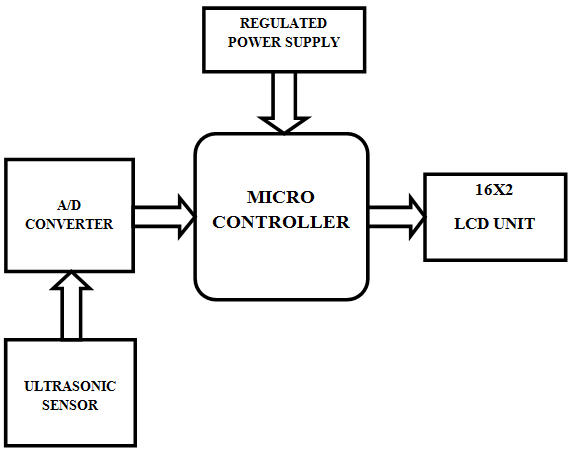

COMPONENTS USED:

- Microprocessor development board

- AT89C51

- IR SENSOR

- LCD

Download School Bag Security Project

This project was developed with an 8051 Microcontroller.