The growth or development of any nation in the world is purely depends up on the agriculture production. Traditional methods of sowing seeds manually consume lot of time and also it may not be accurate because of human errors.

Maintaining uniformity in seed planting can increase the sowing efficiency, there by to over come all these problems, these days former’s are using automatic sowing machines.

In this regard to enhance the technology in the field of sowing machines, mainly to increase the sowing efficiency, this project work is taken up, which is designed as programmable such that distance between the seeds in ‘X’ and ‘Y’ directions (seeds are supposed to be planted) can be programmed independently.

The Automatic Sowing Machine designed here is quite useful for the large cultivated areas, when compared with man power many acres can be planted with seeds within less time, therefore to prove the concept practically, for the demonstration purpose a proto type module with less speed is constructed with microcontroller unit.

The mechanical transmission section is constructed with four different motors, with the help of one higher rating stepper motor, the entire machine along with seeds container is designed to travel in forward and reverse directions.

Using another higher rating stepper motor, the seeds container arranged over the vehicle at front side is designed to travel in horizontal in both the directions.

Using one reduction gear mechanism DC motor, the seeds container is pulled down for planting the seed through pipe. Similarly using another simple DC motor, the seeds container is vibrated for free movement of seeds through pipe.

In addition to these four motors, a solenoid coil is used to control the seeds. The detailed description of entire process is provided in following chapters.

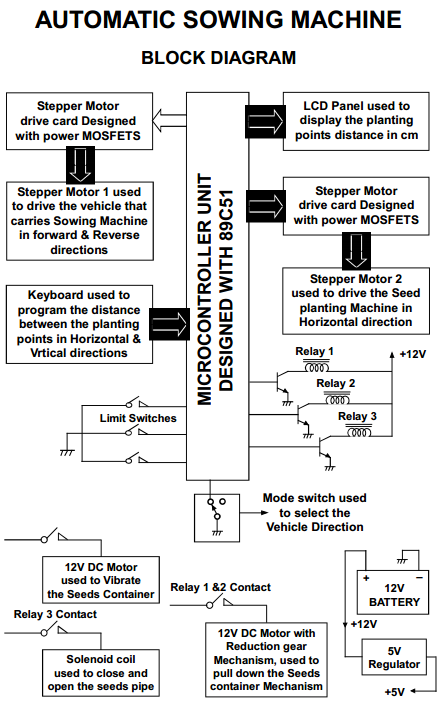

AUTOMATIC SOWING MACHINE BLOCK DIAGRAM

- Stepper Motor drive card Designed with power MOSFETS

- Stepper Motor 1 used to drive the vehicle that carries Sowing Machine in forward & Reverse directions

- Keyboard used to program the distance between the planting points in Horizontal & Vrtical directions

- LCD Panel used to display the planting points distance in cm

- Stepper Motor drive card Designed with power MOSFETS

- Stepper Motor 2 used to drive the Seed planting Machine in Horizontal direction

MICROCONTROLLER UNIT DESIGNED WITH 89C51

- 12V DC Motor used to Vibrate the Seeds Container

- Solenoid coil used to close and open the seeds pipe

- 12V DC Motor with Reduction gear Mechanism, used to pull down the Seeds container Mechanism

12V BATTERY

5V Regulator