Abstract

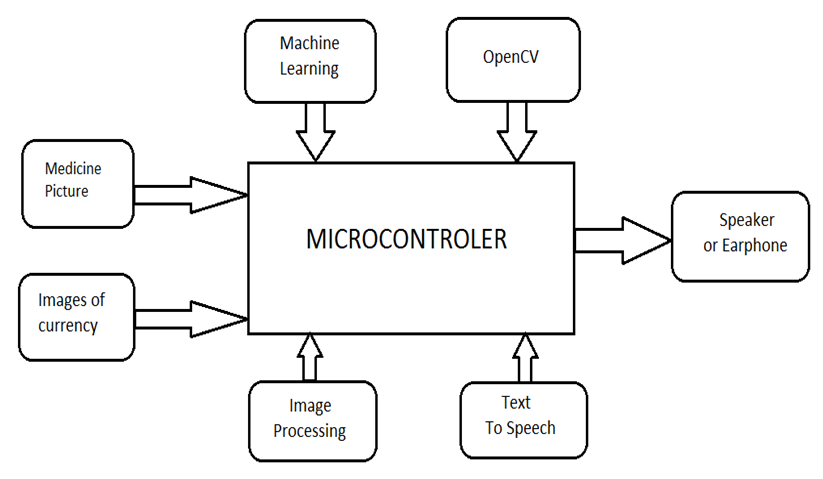

This Smart & Secure Helmet IoT Project is aimed at using the concept of the Internet of Things (IoT) and chemistry with the rider’s helmet to provide extensive safety, guidance, and health care features. The following features are planned to be implemented in a phase-wise manner in the project :

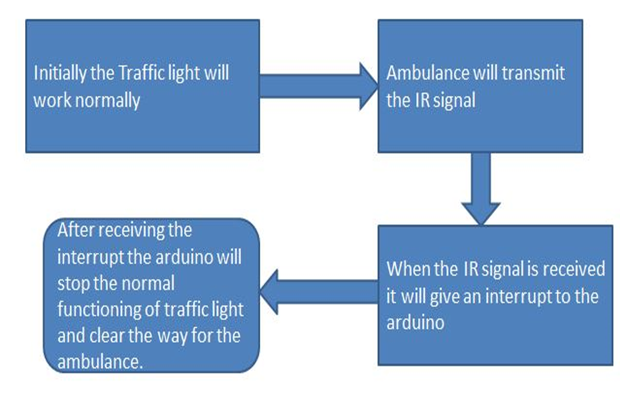

1. Internet of Things(IoT) based traffic emergency system

2. Internet of Things(IoT) based traffic guidance system

3. Extensive protection from sunstrokes

4. GPS tracking

All these facilities are to be implemented on the helmet with maximum cost efficiency to make the final product within the reach of the Indian common man.

Goal

The goal of this project is :

- To provide advanced traffic safety mechanisms through IoT to the people at affordable costs.

- To provide IoT-based traffic guidance system to the people – first target: Tier-1 cities in India

- To provide extensive protection from sun strokes, especially during the hot summer season in India

- To make this project an innovative platform for many other applications like Easy GPS tracking, Health sensor, etc.

Motivation

There has been a multiple-fold rise in the number of road accidents in recent days and many times, emergency services have faced difficulty in a timely response to the situation.

In large cities, sometimes the emergency services find it difficult to locate the spot of the accident based on a phone call.

Companies(logistics, customer service) face difficulties in tracking the vehicles of their employees

Even with the heavy risk of not wearing a helmet, People do it as they find it inconvenient to wear a helmet in hot humid sub-Continent conditions. Our new chemical system compartment in the helmet solves it.

All these situations prompted us to look into the possibility of IoT coming up helping people in these cases and we found out that in the initial phases of our project, we can use the helmets used by people while driving. Later the same technology can be used on other vehicles to provide an all-around extensive safety mechanism.

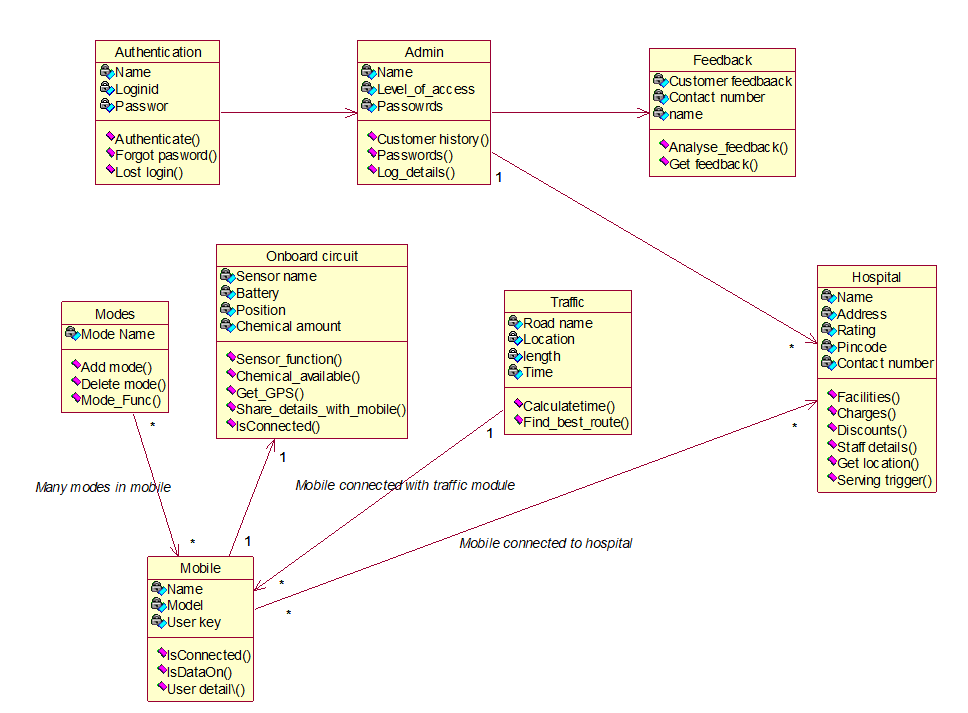

Class Diagram:

ADVANTAGES

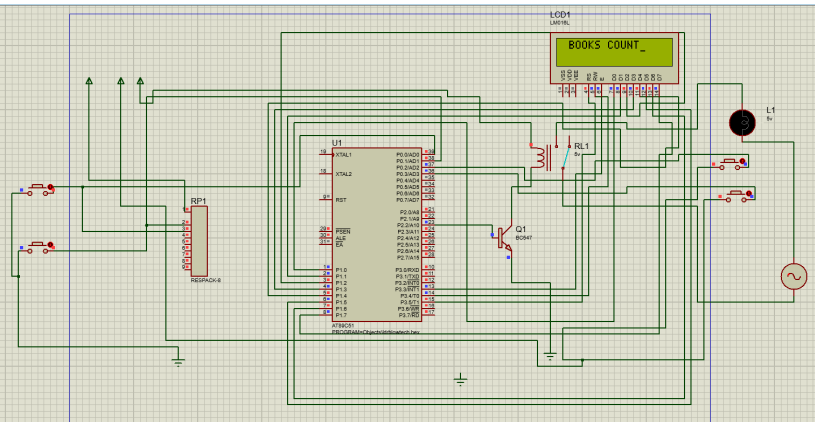

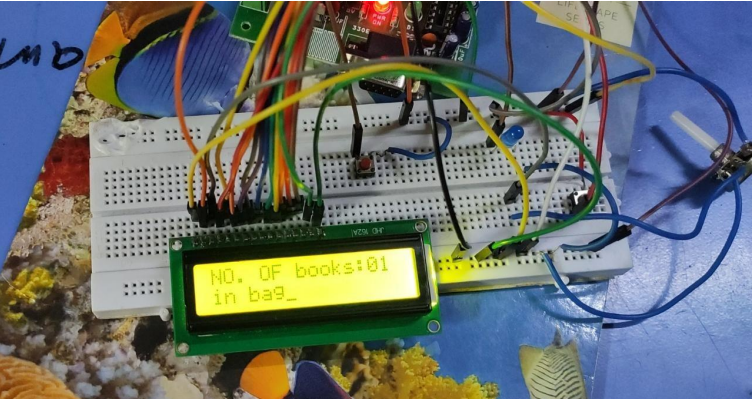

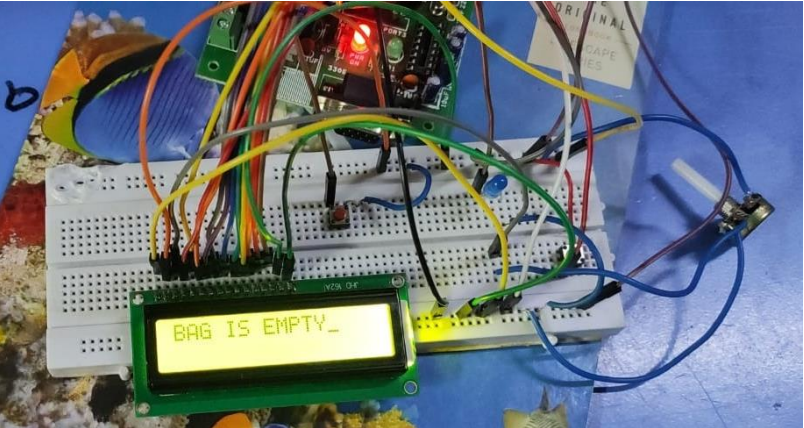

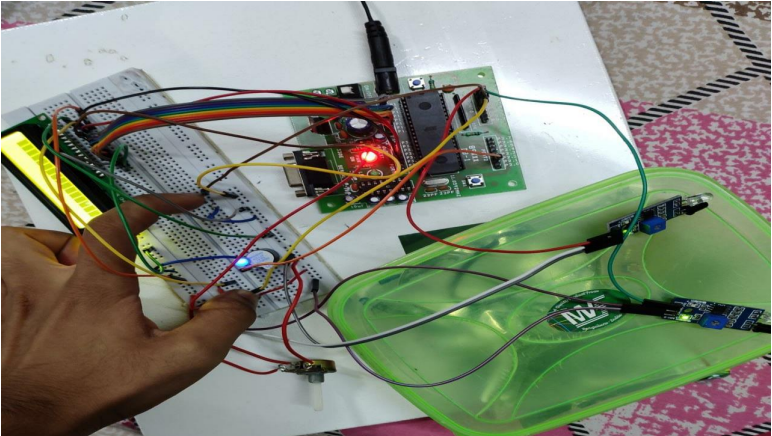

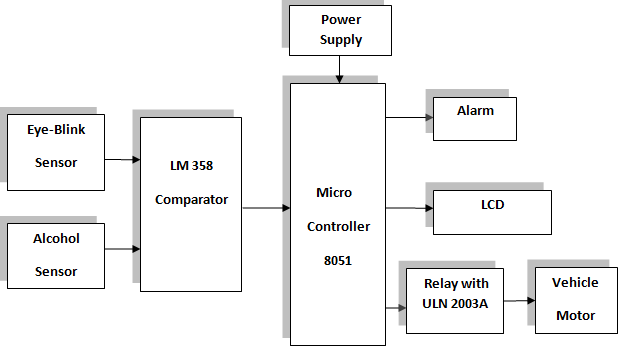

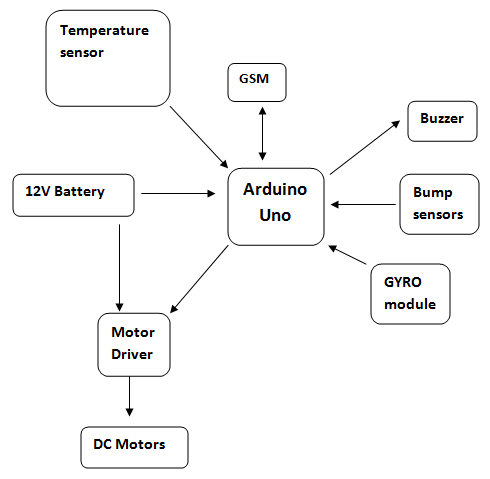

The helmet will be mounted with appropriate sensors at appropriate positions on the helmet. They are calibrated to sense high impact due to an accident or crash.

Once they detect the designated input, the rider’s location is immediately sent to a cloud of hospitals, and the nearest hospital is notified about that so that the ambulance can reach the spot immediately.

1. Immediate response to any accident by the emergency services since all of them become a part of the network (of things).

2. The location of the accident is too updated to the emergency services so that finding the location won’t be much trouble.

3. Details of the personnel are also updated to the emergency service center so that formalities of paperwork may be completed beforehand.

4. Continues tracking of employees for Companies like logistics, customer service, etc.

5. Proper Traffic Guidance using Google Services.

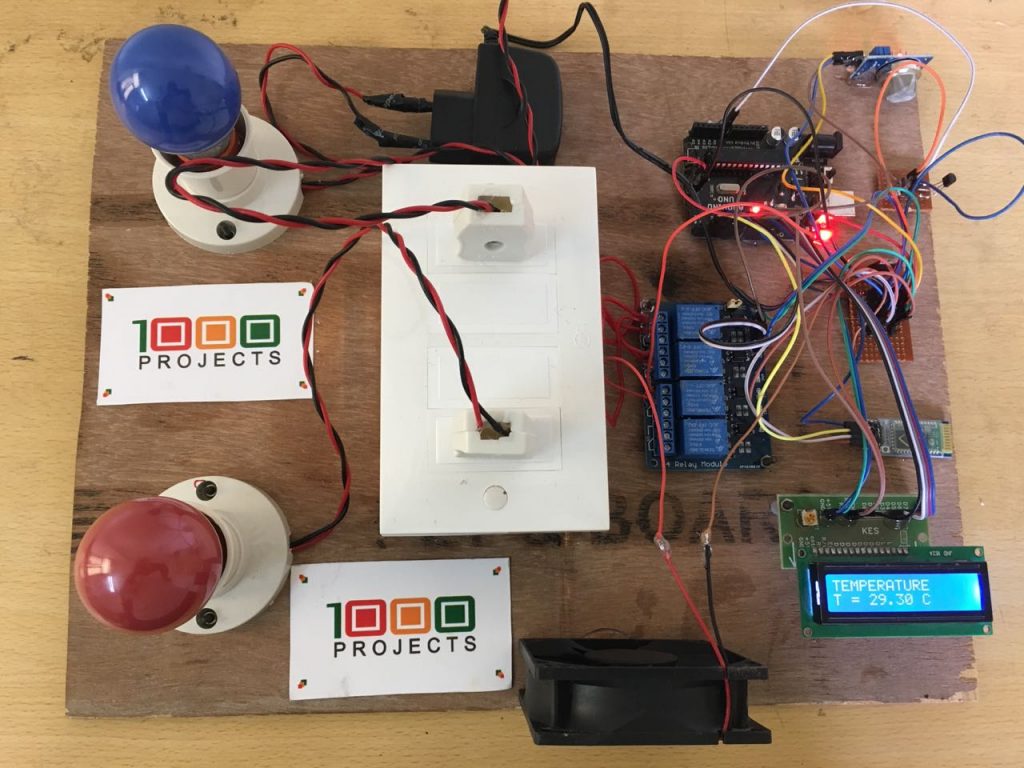

6. Humidity reduction inside Helmet.

7. Many inbuilt Bluetooth facilities like automatic call acceptance (while driving) etc.

Conclave on the Internet of Things provided us with exposure to the applications of the concept of the Internet of Things (IoT) and several other creative approaches that solve day-to-day problems by invoking the interconnection and sharing between the day-to-day products.

Apart from the conclave, we would like to appreciate the suggestions and help from the faculties which proved to be a priceless booster to our project.

We are a team dedicated to the research and development of creative solutions to day-to-day problems. We aim at creating smart, simple, innovative ad cost-effective solutions which could be affordable for the common man of India.

Future Work

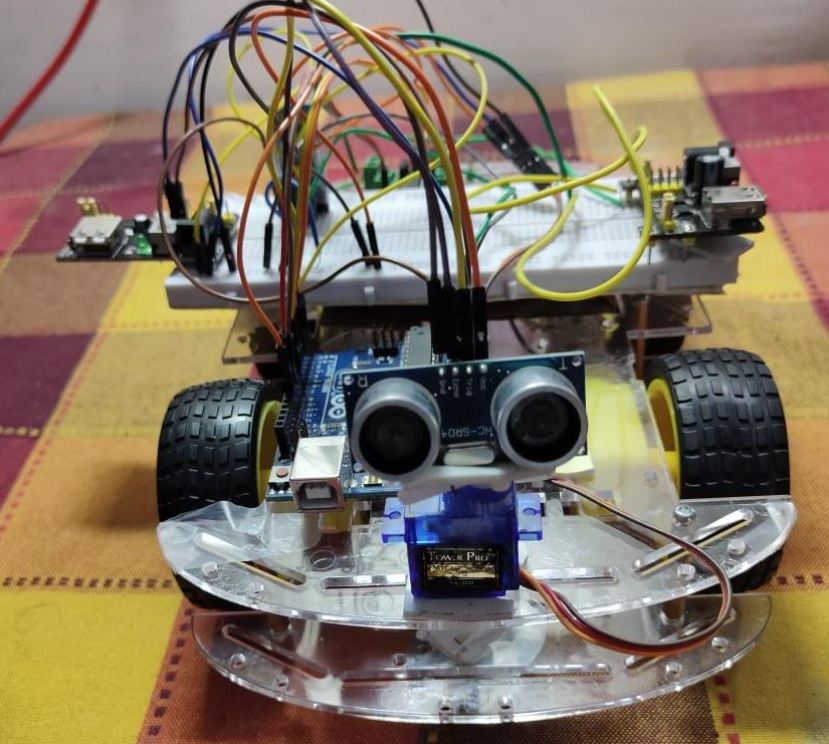

PROTOTYPE-II: To implement a traffic guidance system using Google services.

PROTOTYPE-III: To implement a fully integrated traffic safety and guidance system