Maintenance division in DOE is responsible for the installation and commissioning of the machines and also for their maintenance located at six different shops. The main activities of maintenance involves preventive and breakdown maintenance.

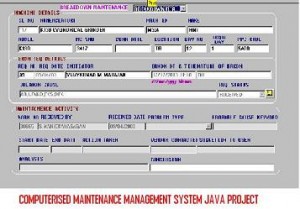

The Development of Computerised Maintenance Management System (CMMS) module which is a part of the Integrated Manufacturing Information System (IMIS), facilitates in maintaining the information about installation & commissioning of machine tools, their re_installation, upgradation and retrofitting details.

It also helps in maintaining the records about preventive maintenance planning & schedule, breakdown maintenance details, spare parts planning and inventory management. Based on the records in database and information produced by flexible queries, appropriate decision can be taken by the management for future course of actions.

In addition to the basic task of pursuing Breakdown maintenance & Preventive maintenance, the failure rate & performance aspects have to be assessed time to time which serve to evolve strategies for higher availability.

The control / monitor of work orders, allocation & maintenance related data; in manual mode is cumbersome & time consuming where budget control systems Projects can be useful. As such to make faster & reliable information system pertaining to maintenance activity, the PC based system has been planned.

SCOPE

The scope of this project is to develop Computerised Maintenance Management System. The main activities of CMMS involves preventive and breakdown maintenance. There are few maintenance projects like Crime Record Management system which can be useful as reference for management project.

OBJECTIVES

- To monitor/control the on line Breakdown & preventive maintenance actions.

- Elimination of Manual documentation and record keeping.

- To develop centralized database which enables every one like shop floor, maintenance, process planner to monitor the machine status & know machine details, machine history and its performance.

- To develop the knowledge base for maintenance activities, like breakdown, preventive maintenance to do performance study of machines which enables to take decision on the machines like up-gradation / retrofitting or disposal.

- To track inventory details and wok schedules & planning.

pls send online shopping project using java servlets,jsp,javascript and mysqlserver

Please send me mini project

Is there a source code? Can you please share a source code.

Thank you.