The integration of such sensors in cargo has paved the way for intelligent transportation. These integrated systems are competent in delivering reliable details about the quality of the goods during their depository time.

To reach this goal, we use a variety of sensors suited for monitoring the safety of food products and goods by recording the transition of parameters like temperature, humidity, and air quality, fire detection.

This information is transmitted wirelessly to the IBM cloud providing an interface where the authorized person can observe the product quality over time and also receives alert messages in case of bad air quality and abnormal conditions.

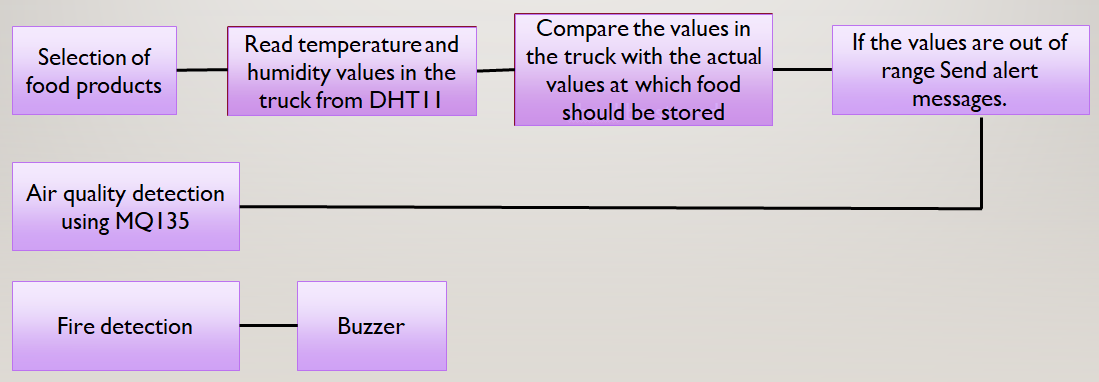

Block Diagram:

An Intelligent Cargo Management System app is designed for selecting the type of goods to be stored in the truck, for door automation, and for retrieving the values from the sensor.

Initially, the authorized person of the truck has to select the type of goods stored in the truck through the Cargo Management System app. Based on the selection, the temperature and humidity values at which the goods are supposed to be stored will be known. Using the DHT11 sensor, the actual temperature and humidity inside the truck can be known.

The temperature and humidity values can be obtained from the app. By comparing these values, a message will be sent to the authorized person asking him/her to turn on the AC or the heater in any abnormal conditions.

The air quality inside the truck is constantly monitored using MQ135 sensor. If the quality of the air inside the truck is bad, a message is sent to the authorized person regarding the same.

Through this goods can be maintained in constant conditions and their quality is maintained for a longer time. A fire sensor is also deployed in the truck to detect fire. If the fire is detected, the buzzer rings alerting the driver of the fire. The door of the truck is automated using a servo motor.

The authorized person of the truck can open or close the door of the truck using the Cargo Management System app.