This Gentamycin Chemical Engineering Project Report is about GENTAMICIN, which is prepared for B.E (CHEMICAL) degree students. The project report consists of six chapters and each chapter has detailed explanation of the subject which helps to understand the concept of GENTAMICIN. The fourth generation antibiotic belongs to a group of aminoglycosides is GENTAMICIN.

An aminoglycoside antibiotic named GENTAMICIN is used to treat many types of bacterial infections. It can be taken through injection or applied in a cream to the skin or through drops to the ears and eyes.

The derivation from the fungi of genes MICROMONOSPORA is an antibiotic, GENTAMICIN. It is synthesized by MICROMONOSPORA, a genus of Gram-positive bacteria widely present in the environment (water and soil).

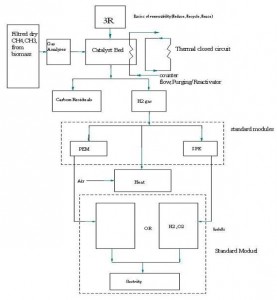

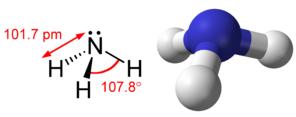

GENTAMICIN is an antibiotic complex consisting of the closely related components, GENTAMICIN C1, C2, C1a produced by fermentation of MICROMONOSPORA PUPUREA or M. ECHINOSPORA and their variants. GENTAMICIN is a bactericidal antibiotic that works by binding the 30S subunit of the bacterial ribosome, interrupting protein synthesis.

It is administered intravenously, intramuscularly or locally to treat infections. It seems to be totally eliminated unaltered in the urine. Urine must be collected for many days to recover all of a given dose because the drug binds avidly to certain tissues. It is also used during orthopedic surgery for the setting of cement. At high doses of GENTAMICIN may cause Kidney and ear damage.

Gentamycin Chemical Engineering Project Report Conclusion:

GENTAMICIN is an AMINOGLYCOSIDE isolated from MICROMONOSPORA PURPUREA. It is an important agent for the treatment of many serious gram-negative bacillary infections. It is the aminoglycoside of the first choice because of its low cost and its reliable activity against all but the most resistant gram-negative aerobes.

The GENTAMICIN protection assay enables researchers to quantify the ability of pathogenic bacteria to invade eukaryotic cells. It takes advantage of the fact that GENTAMICIN is not able to penetrate eukaryotic cells.